What is a paper cup machine?

A paper cup machine is a piece of equipment used to manufacture paper cups. It involves a series of processes including paper feeding, sealing, bottom punching, heating, knurling, and discharging to produce the final paper cups.

What is the function of paper cup machine?

The function of a paper cup machine is to automate the production of paper cups. It performs several steps including paper feeding, sealing, forming, and cutting to create finished paper cups. The Paper Cup Forming Machine takes care of the entire process, from rolling the paper blanks to sealing the bottom of the cups, ensuring efficient and consistent production. It enables mass production of paper cups with high speed, accuracy, and reliability.

How many quanties of cups can be made in 1 ton paper materials?

It can make 400000 pcs of 4 OZ cup by 1 ton of paper fan with 160gsm it can make 240000 pcs of 8 OZ cup by 1 ton of paper fan with 230gsm it can make 150000 pcs of 12 OZ cup by 1 ton of paper fan with 280gsm.

What are the raw materials used in paper cup production?

The raw materials typically used in paper cup production include PE (polyethylene) coated paper or PLA (polylactic acid) coated paper, which are food-grade materials suitable for containing beverages.

What types of paper cups can be produced with a paper cup machine?

Paper cup machines can produce a variety of paper cups including single-wall paper cups, double-wall paper cups, ripple cups, and other specialized designs.

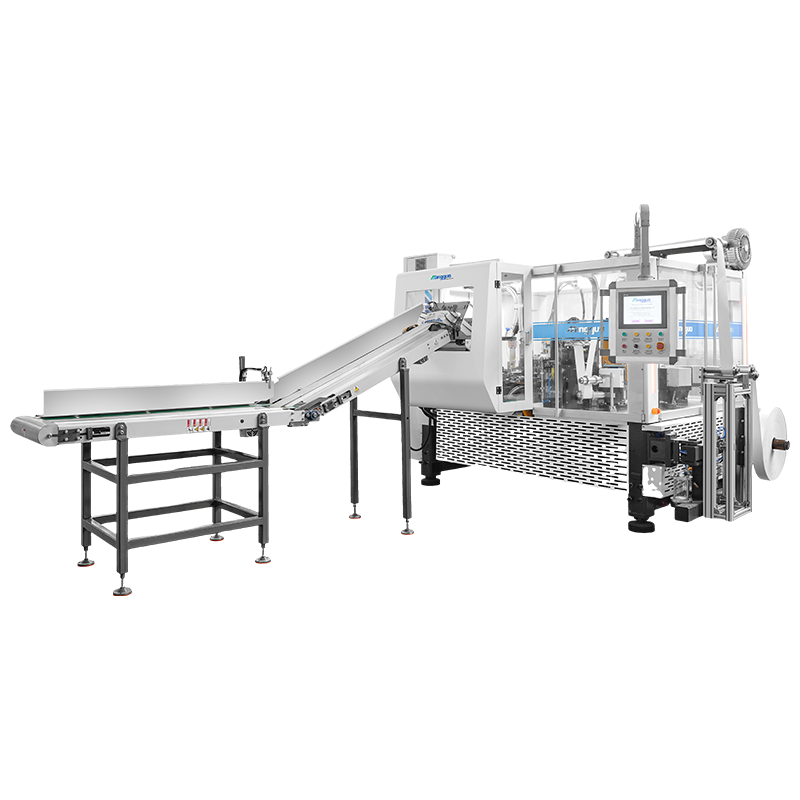

How does the Paper Cup Machine in Mingguo work?

Paper feeding --Paper Fan Preheating--Ultrasonic sealing --Bottom Paper

Preheating1-- Bottom Paper Preheating 2--Bottom Paper Folding--Bottom

Knuring--Top Curing1--Top Cuning2--Cup Ouput

What industries is the machine suitable for?

food industry, to manufacture various cups, majorly coffee cups, teacups, milk cups, etc.

What are the production capacity and speed of a typical paper cup machine?

Production capacity and speed vary depending on the model and specifications of the paper cup machine. However, modern machines are capable of producing thousands of cups per hour.

What are the key features to consider when choosing a paper cup machine?

Key features to consider include production capacity, cup size versatility, automation level, power consumption, maintenance requirements, and after-sales support.

How can a user properly maintain a paper cup machine?

1.Reading the user manual.

2.Establishing a regular maintenance schedule.

3.Cleaning and lubricating moving parts.

4.Inspecting for wear and replacing damaged components.

5.Checking electrical connections for security.

6.Monitoring temperature and pressure settings.

7.Examining seals and joints to prevent leaks.

8.Providing operator training and encouraging issue reporting.

9.Keeping the machine clean inside and out.

10.Maintaining a spare parts inventory.

11.Ensuring safety features and emergency stops work correctly.

12.Keeping records of maintenance activities.

13.Considering periodic professional servicing.

14.Staying informed about manufacturer updates and improvements.