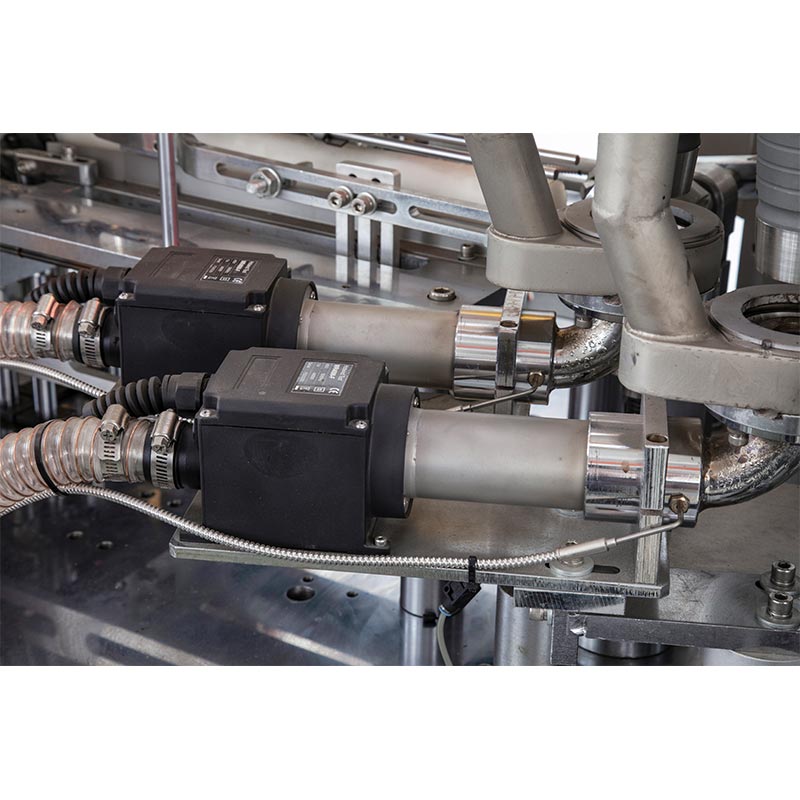

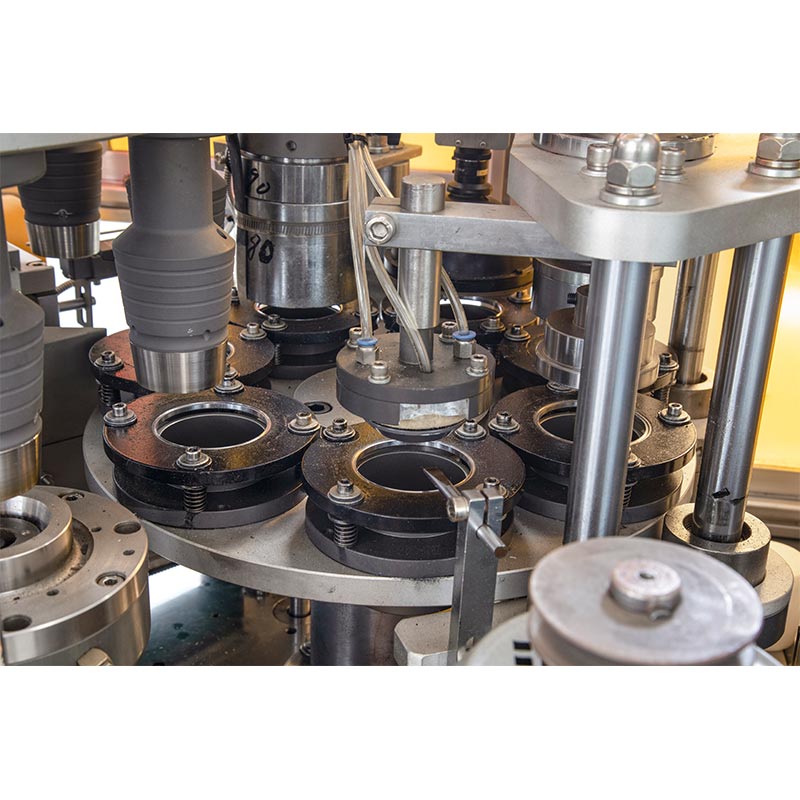

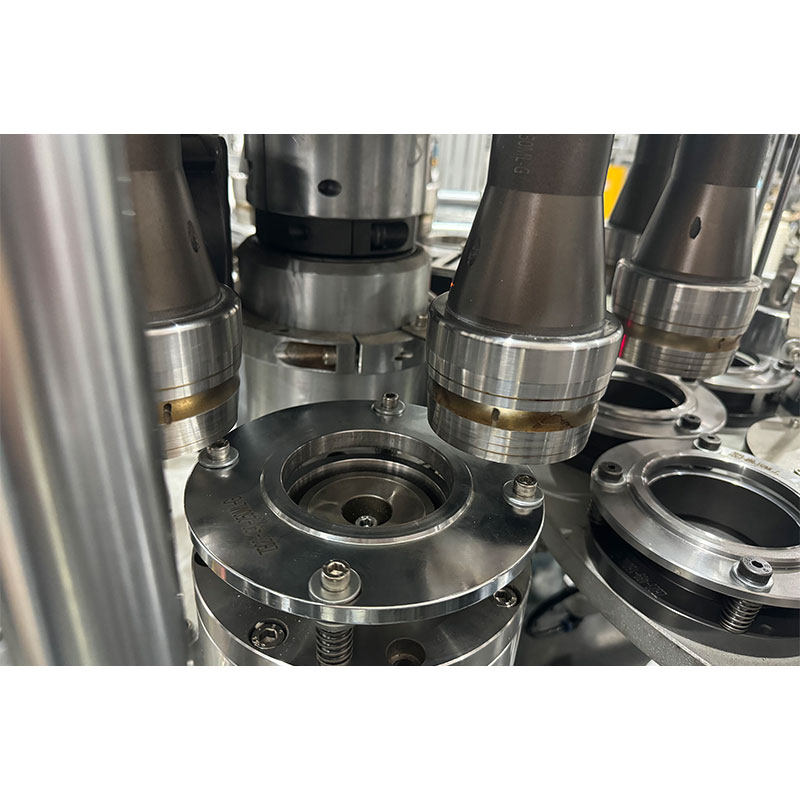

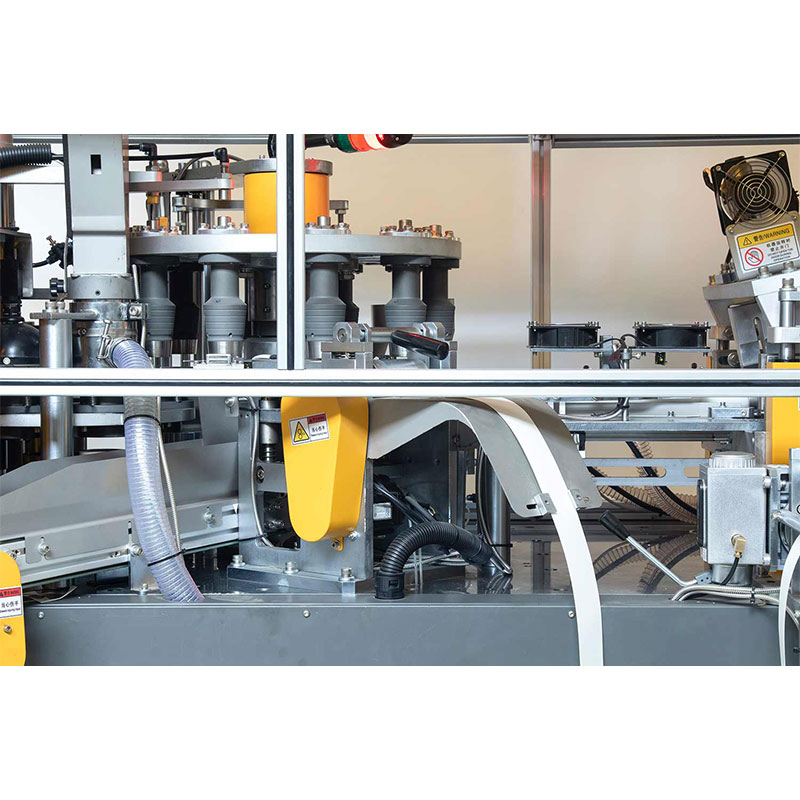

1. The MG-G800 high speed paper cup forming machine also applies many well designed techniques and devices: spray lubrication is mainly applied to decrease the abrasion of components; the imported Lister heater is utilized for sealing cup body and bottom; silicon oil flow is precisely controlled by an electromagnetic valve. This high-yield paper cup forming machine conducts two forming steps, rotating curling and heating& forming. By doing so, it produces cups with high strength and uniform size.

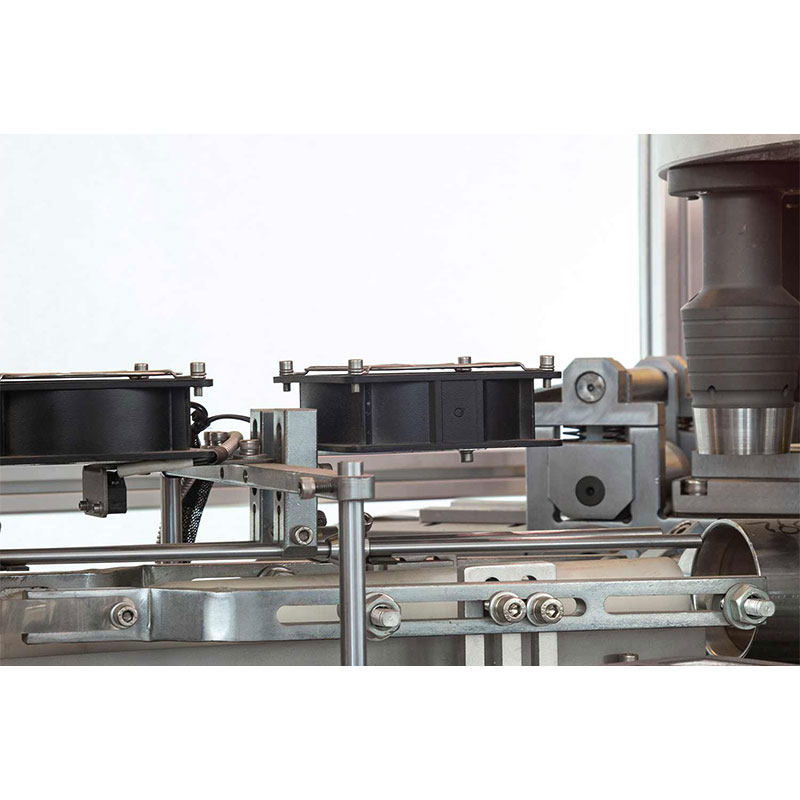

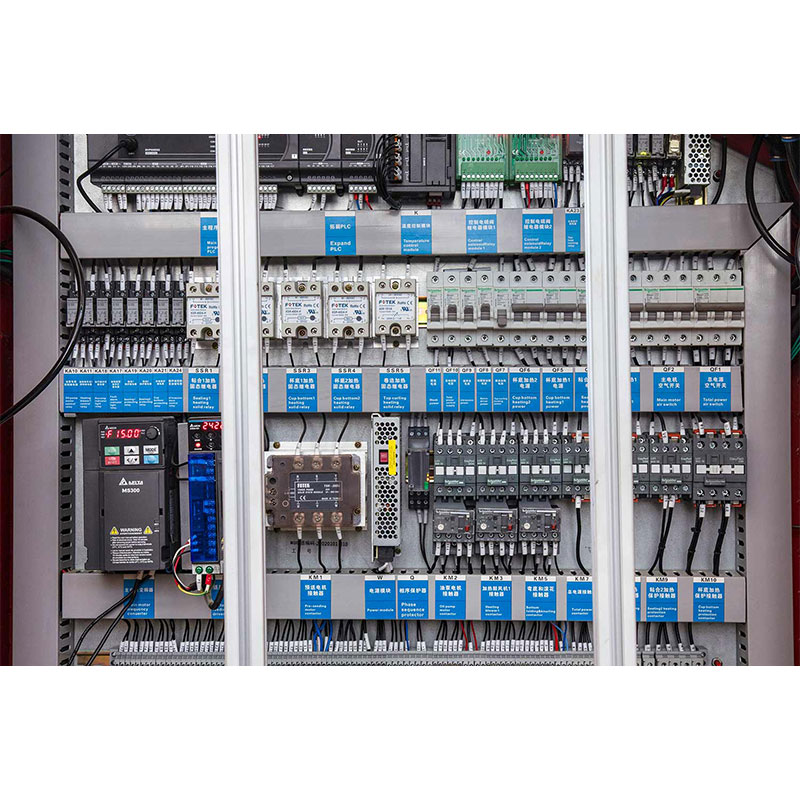

2. When it comes to PLC control, by utilizing a photoelectric sensor and servo control feeder, the paper cup forming machine ensures a high speed and stable operation and achieves a significant decrease in labor cost. In addition, this automated paper cup forming machine will automatically shut down when any malfunction is detected.

3. The paper cup forming machine with the assistance of a CCD image detecting system (optionally), cups that are broken, stained or defective can be picked out. This effective system achieves no manual intervention and reduces secondary contamination of product.

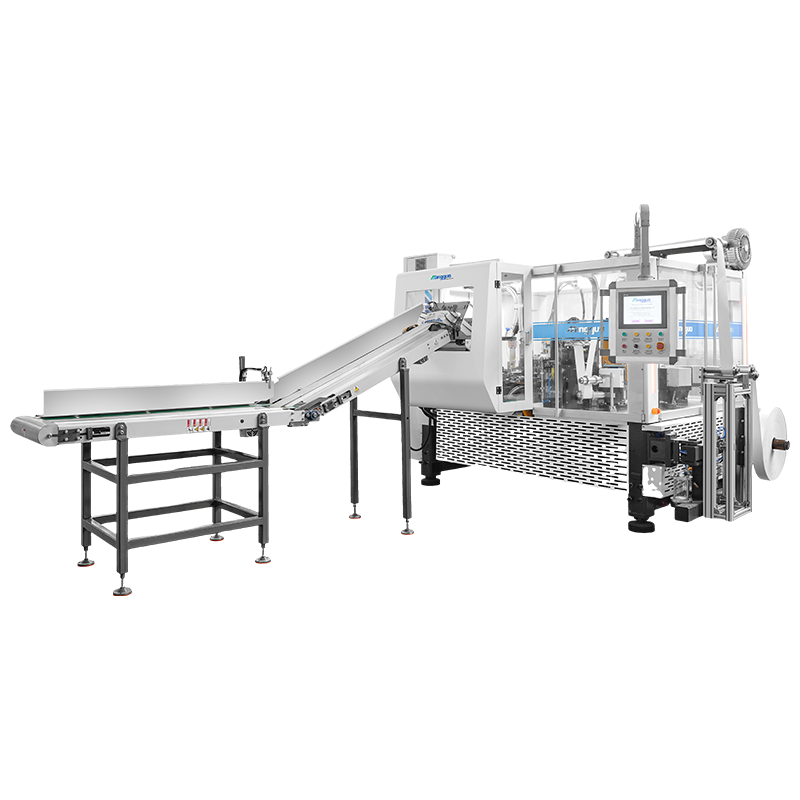

4. This kind of paper cup forming machine equals to one piece of equipment that integrates all cup making procedures, including paper feeding, sealing, cup bottom feeding, heating, knurling, cup-mouth curling, discharging, testing and counting. MG-G800 High speed paper cup forming machine is an ideal choice for making cups of 50-135mm high.