Behind every delicious ice cream cone, frozen treat, and roadside stall dessert lies an unsung hero: the high-speed paper cup machine. These sophisticated manufacturing systems quietly revolutionize how food vendors serve summer delights.

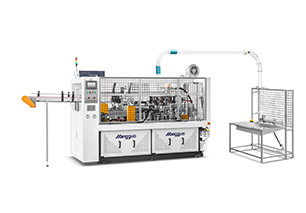

Modern paper cup making machines are engineering marvels capable of producing 120-200 paper containers per minute. Utilizing advanced PLC control systems and precision components, these automated systems transform laminated paper into reliable food containers with minimal human intervention. The latest models feature sensor monitoring that automatically stops operation when issues are detected, ensuring consistent quality and reducing waste.

These machines efficiently handle various materials, including PE-coated paper, double PE-coated paper, PLA-laminated paper (for biodegradable options), and even aluminum foil paper. This versatility allows dessert vendors to choose the perfect container for their specific products, whether they're serving frozen yogurt, shaved ice desserts, or traditional sugar water soups.

The world of frozen desserts requires specialized containers that standard paper cups cannot provide. For classic ice cream cones, paper cone sleeves serve as both hygienic barriers and structural support. The ice cream cone cup manufacturing machines specialize in producing these conical containers with precise dimensions to fit perfectly over baked cones.

Meanwhile, the popular tube-shaped frozen treats like Calippo require equally specialized packaging. The Ice Tube (Calippo) Forming Machine addresses this need with precision engineering that creates uniform paper tubes ideal for frozen novelty treats. These machines can typically produce between 800 and 2,000 units per hour, ensuring adequate supply even during peak summer demand.

These specialized machines offer customization options, allowing producers to adjust dimensions according to their specific needs. For instance, some cone paper machines can produce cones with angles of 15° or 18°, with lengths ranging from 120 to 200 mm. This flexibility enables dessert businesses to create distinctive packaging that sets their products apart in a competitive market.

Traditional summertime desserts like pudding, fruit combinations, and sugar water soups—typically served in paper bowl containers—are also as popular as frozen desserts. These broader, shallower containers need different production processes than paper cups.

Paper bowl machine systems, capable of producing up to 120 bowls per minute, specialize in these versatile containers. These machines can often handle a variety of paper weights from 100 to 350 GSM, giving various strength requirements depending on whether the bowl will hold lighter fruits or heavy liquid-based desserts.

Summer creates unique challenges for dessert container manufacturers. Demand spikes dramatically during heatwaves, requiring producers to ramp up production quickly. High-speed paper cup machines with their impressive output capacities become invaluable assets during these periods.

The seasonal nature of dessert consumption means downtime during slower months must be balanced with peak season production capabilities. Modern paper container machines address this need through flexible production schedules, quick changeover between container types, and reliable operation even after periods of inactivity.

Additionally, summer desserts often require special container features like double-layer walls for better insulation or special barriers to prevent condensation from making containers soggy. Advanced paper cup making machines can accommodate these special requirements through adjustable settings and modular components.

Selecting the appropriate paper container manufacturing machine requires careful consideration of several factors. Production volume needs, container types, material preferences, and available space all play crucial roles in determining the ideal equipment for your business.

For businesses focusing primarily on beverage service, a dedicated high-speed paper cup machine with an output of 120-150 cups per minute might suffice. Those requiring more versatility might prefer systems that can switch between producing paper cups, paper bowl containers, and even specialized formats like ice cream cone cup sleeves.

Reliable after-sales support is another critical consideration, especially for businesses operating in remote areas. Look for suppliers offering comprehensive warranty coverage (typically 1-3 years), video technical support, online assistance, and readily available spare parts.

With modern paper cup making machines and specialized equipment for making ice cream cone cups and paper bowls, dessert restaurants can confidently meet seasonal demand.

These cutting-edge gadgets go beyond basic industrial tools and are calculated investments in business growth and customer delight. Because they ensure continuous container quality, production efficiency, and the capacity to design customized packaging, paper container manufacturing machines are truly the most beneficial equipment for delicious summertime desserts.

Are you ready to improve your ability to package desserts? To learn how our range of high-speed paper container machines can keep your business cool and busy the whole peak season, contact us right now.

Paper cups specifications:

4-16oz (can be customized by max.26oz)

(100-450ml)(mold exchangeable)

Top:55-105mm

Height:60-135mm

Bottom:55-75mm

Paper cups specifications:

(100-350ml)(mold exchangeable)

Top: 55-90mm

Height: 60-110mm

Bottom: 40-65mm

Paper cups specifications:

150-180 pcs/min

2-12oz (75-300ml) (mold exchangeable)